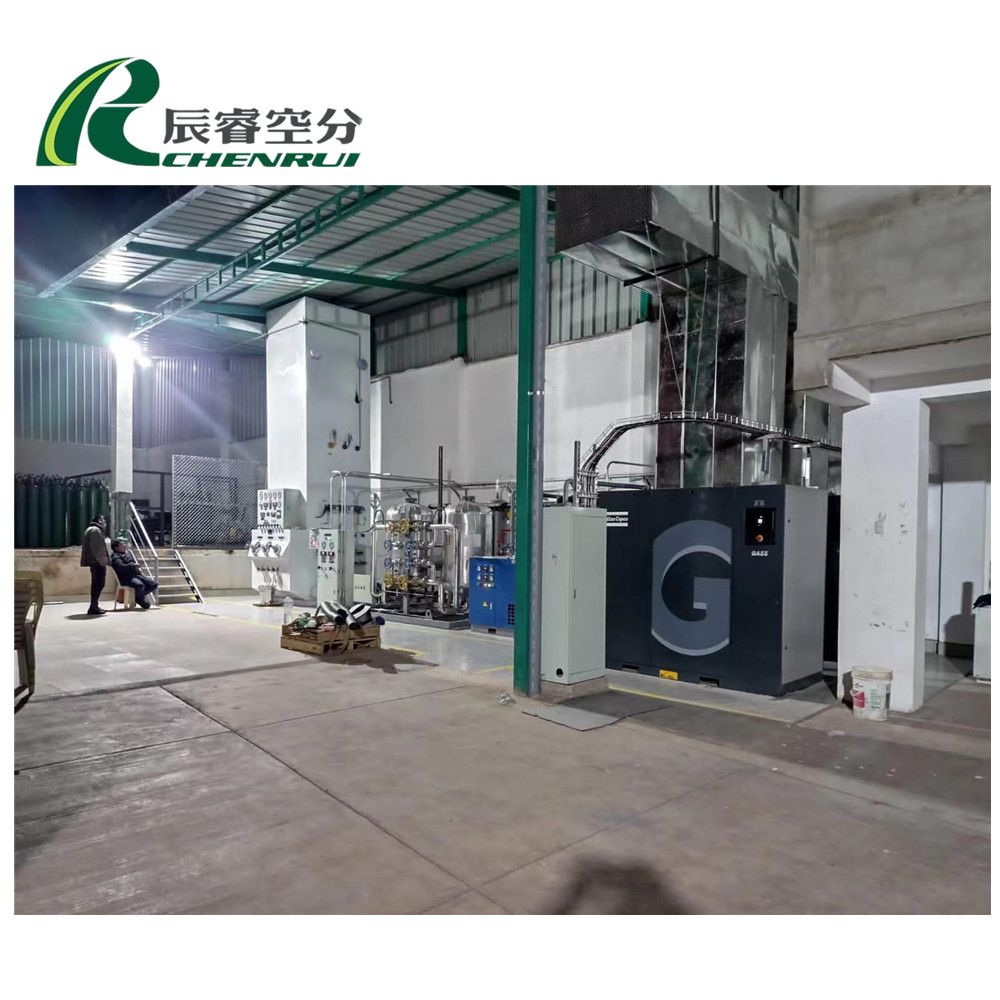

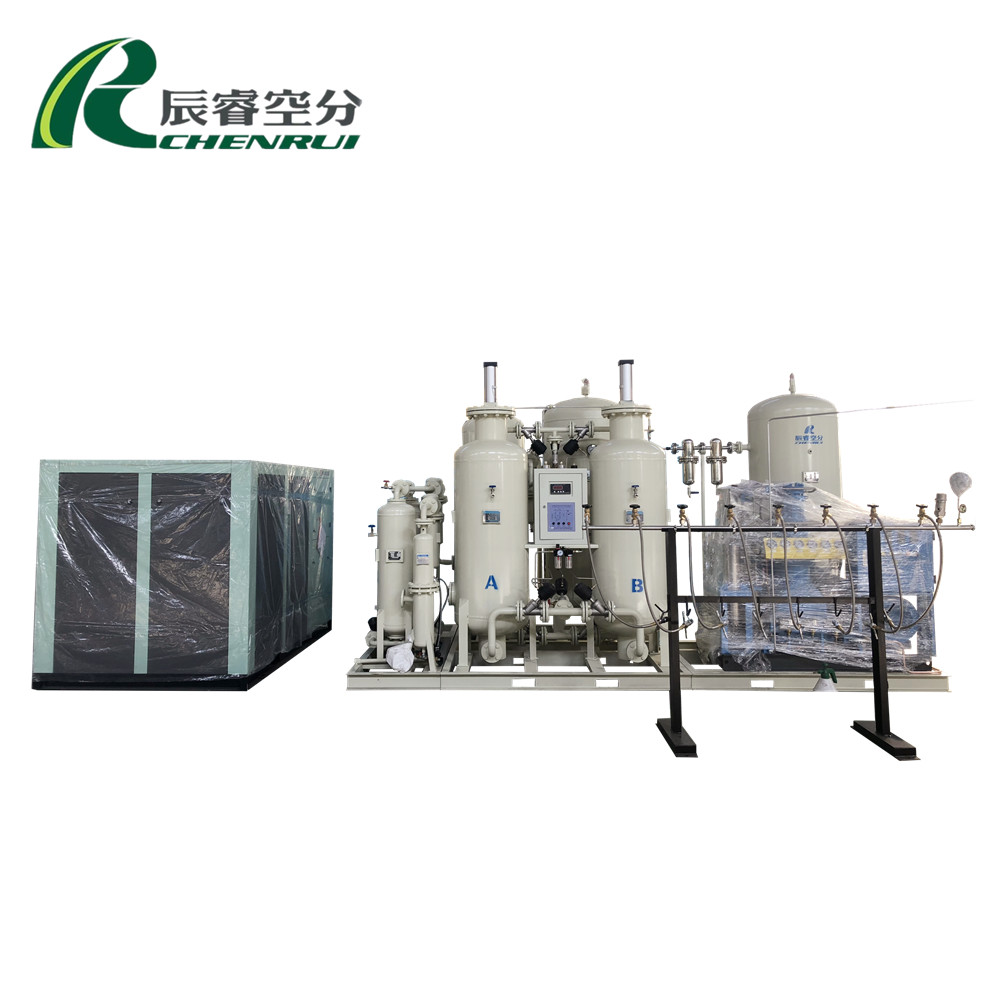

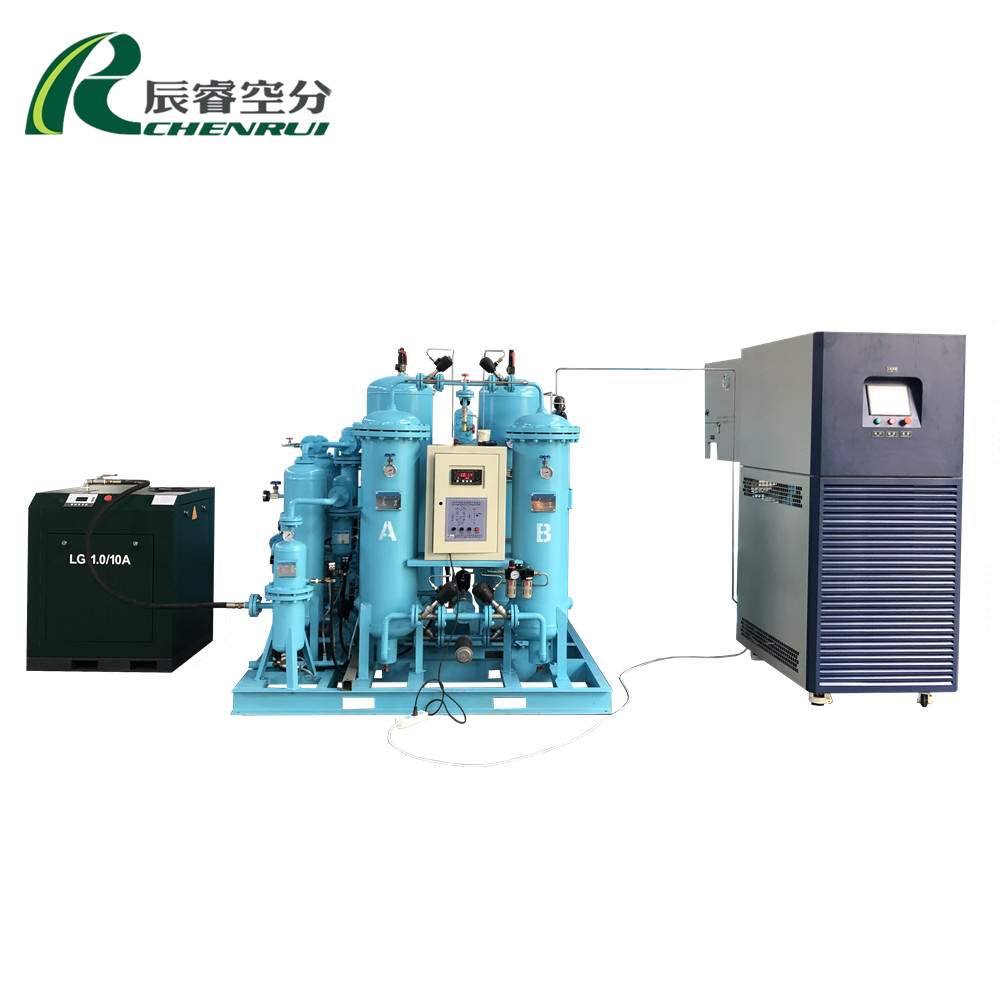

PSA Nitrogen Generator

Technical Parameters

Nitrogen capacity | 3-3000Nm3/h |

Nitrogen purity | 95-99.9995% |

Output pressure | 0.1-0.8MPa(1-8Bar) adjustable / or as customer’s requirement |

Working Principle

PSA nitrogen generator and PSA oxygen generator have similar principle. Molecular sieve as an adsorbent under the principle of pressure swing adsorption (PSA), will get nitrogen/oxygen from compressed air.

Perfect process design get high performance. Unique vacuum molecular sieve filling system and impacted technology increase the life of molecular sieve. Skid-mounted structure makes installation and transportation more convenient. With DCS controller system and remote output and control system. High automatic, unmanned operation.

Application

PSA Nitrogen generator system is widely used in Food packing; Food storing; Electric & Electronic industry ; Petro-gas & Oil field; Chemicals & Petero-chemicals; Coal-mine;Pharmacy; SMT; Lab; Fired-resistance; Air diving and etc.

PSA Technical Features

1.Full Automation

All systems are designed for un-attended operation and automatic nitrogen (oxygen) demand adjustment.

2. Lower Space Requirement

The design and instrument makes the plant size very compact,assembly on skids,prefabricated from factory.

3. Fast Start-up

Start-up time is only 30 minutes to get desired nitrogen (oxygen) purity. So these units can be switched ON&OFF as per nitrogen(oxygen) demand changes.

4. High Reliability

Very reliable for continuous and steady operation with constant Nitrogen purity.Plant availability time is better than 99% always.

5. Molecular Sieves life

Expected Molecular sieves life is around 15-years , so whole life time of PSA nitrogen (oxygen) generator no replacement costs.

6.Adjustable

By altering flow,you can deliver nitrogen with precisely the right purity.